ethylene mini flow measurement

email: porter@microflowmeter.com Shanghai JSN Micro Flow Meter CO.,LTD use advanced scientific managementas a means, relying on Shanghai’s advantages as a key science and educationcity in the country, it has fully utilized resources and actively cooperatedwith Shanghai Jiaotong University, Shanghai’s Fudan University and otheruniversities, and had some achievement, especially in super micro flow,ovalgear flow meter ,coriolis mass flowmeter,electromagnetic flow meter,piston flowmeter,spur gear flow meter,gear pump,gear metering pump. In the past year,ourcompany had establish the reliable and lasting research cooperation with ChineseAcademy of Sciences, Peking University, Norwegian University and other researchinstitutes.Now company is involved in polyurethane, fuel consumption,automotive, dispensing robots, semiconductors, odorizing equipment, batteries,electricity, telecommunications, petroleum, chemical, coal, metallurgy, waterconservancy, food, medical, machinery and other industries. In futuredevelopment, Shanghai JSN should enlarge and strengthen our company, leadinginto the ranks of companies with international competitiveness, and strive tocreate an international, green, sustainable development of instrumentationcompany.

ethylene mini flow measurement

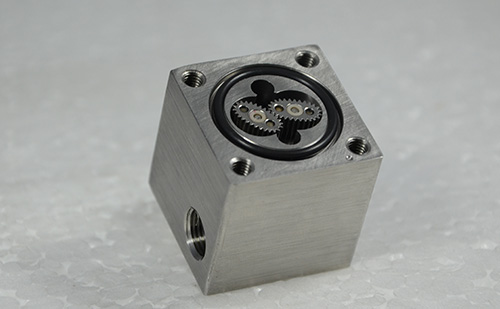

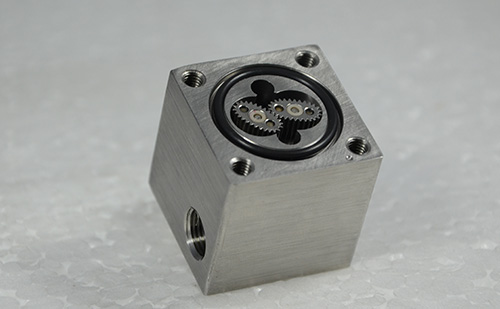

At presentdomestic Oval gear flow meter structure is complex, bulky, bulky, noisy, smallscale, not suitable for low viscosity liquid, the market is more common withDTO series and OGM series. For these problems the country has been unable toovercome, while the Shanghai JiShen instrument Instrument company oval gear Ovalgear flow meter does not have the above problems, such as the same DN25caliber, our model CX-M25-AL, flow range: 0.5 ~ 100L / M, range of 1: 200 orhigher, and weighs only 1.5KG , While the DTO-25, the flow of 600-6000L / H,range ratio of only 1:10, the weight of up to 23KG. All this due totechnological breakthroughs, our chief engineer Tu workers, he is a formerSiemens senior engineer, the use of equipment It is also Siemens CNC MachiningCenter with cutting accuracy up to 0.001mm, which ensures that we produce highquality flow meters.

Whymany customers gradually from the major international brands MAX, OVAL Obar,KRACHT Clarke and other gradually purchased base deep Oval gear flow meter it?Many customers also have questions: why base depth can be reported Oval gearflow meter so good? This stems from our engineers is a former Siemens seniorengineer, the device is also fully adopted Siemens CNC machining center, thecutting height of 0.001mm, to ensure that our flowmeters minimum flow meter canbe measured to 0.1ml / min, which are at home and abroad are Rare, the currentproducts have been awarded the national measurement certificate, and ISO, SGS,CE, after thousands of customers hundreds of conditions medium test, once againwe are very grateful to the recognition of domestic and foreign customers.Attitude, carrying domestic and foreign customers look forward to working hardto make real benchmarking business.

ethylene mini flow measurement

The Ovalgear flow meter is a volumetric flow meter that consists of a flow chamber in achamber and one or several elements that are rotated by fluid flow to form aflow meter. Leakage between the rotating element and the inner wall and theselected working range The internal flow rate is negligible. The rotation ofthe element is transmitted mechanically or by other means to the indicatingdevice to indicate the volume flow of the fluid flowing through.

ethylene mini flow measurement

Technicaldata of Gear type flow meter

Model | K-factor | Minimum flow | Flow range | Accuracy |

G0.025 | 0.025ml | 0.001L/Min | 0.008~2L/Min | 0.5% |

G0.04 | 0.04ml | 0.004L/Min | 0.2~4 L/min | 0.5% |

G0.1 | 0.4ml | 0.008L/Min | 0.01~8L/min | 0.5% |

G0.2 | 0.245ml | 0.01L/Min | 0.16~16 L/min | 0.5% |

G0.4 | 0.4ml | 0.01L/Min | 0.16~16 L/min | 0.5% |

G1 | 1.036ml | 0.02L/Min | 0.4~80 L/min | 0.5% |

What"s the reason for the tiny gear flow meter"s wheels not turning? the reason:1. The filter is clogged.2. Impurities enter the flowmeter and the rotor gets stuck.Treatment measures:1. Clean the filter.2. Check the filter for damage and clean the inside of the flow meter.